Cassava processing

Practical Action

fermented paste is put into hessian or polypropylene sacks and placed in to the press. An

alternative traditional approach is to use rocks to compress the sacks, which allows the

fermentation and pressing to take place at the same time.

Sieving will produce a high quality product with similar sized granules. Larger particles that are

separated during this process are sold as a cheaper grade.

The product should be packed into polythene bags to prevent any moisture being absorbed from the

air. This is especially important in areas of high humidity. The bags should then be stored in a cool

dry location.

Another approach to making cassava flour is to incorporate a

fermentation stage which produces a slightly sour flavour

The basic steps for

product known as Gari. This can be done either during the

dewatering stage or through retting which involves soaking the

whole or cut roots in water for 3 to 5 days until root has

making Gari

Sort

Peel

fermented. The duration of fermentation should be carefully

monitored to ensure that detoxification is complete but the

product must also have an acceptable flavour and texture.

Wash

Cut/grate

Pound or mill

Ferment

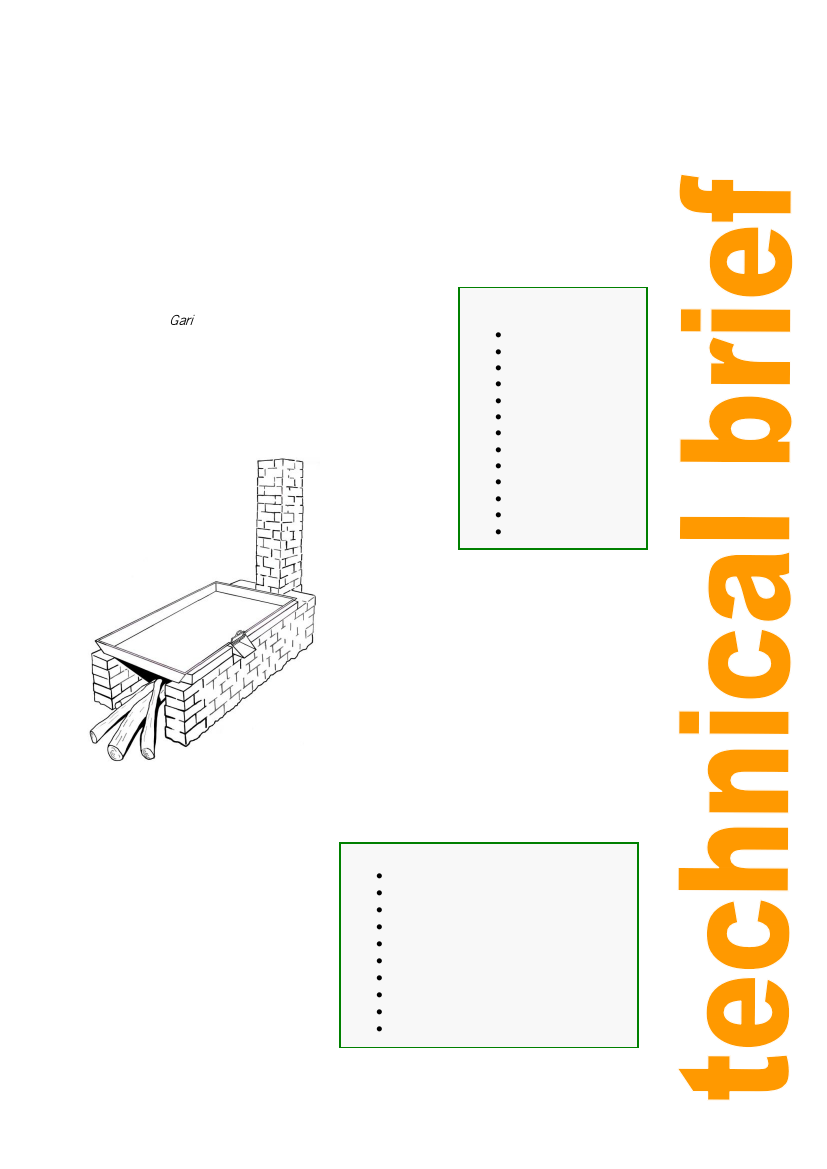

Roasting the

Dewater/dry

flour improves

the storage

capacity. It is

Sieve

Roast

Cool

done in a large,

shallow pan over

Sieve

Pack

a fire, with

Store

constant stirring

with wooden paddles for 20 to 30 minutes. It can

be done with palm oil on its own. Cylindrical

rotating roasters are used for in larger scale

production setups.

Figure 4: Cassava flour roaster

Illustration: Neil Noble/Practical Action

Fufu is made from cassava flour by pounding the

material until a gelatinous sticky product results.

Traditionally this was done using a pestle and

mortar and could take up to an hour. Motorised

pounding machines reduce the amount of work

required. One such design was developed by the

Department of Agricultural Engineering at the

University of Ife in Nigeria.

Making starch

Starch is traditionally used for foods such as

biscuits, bread, and as a base for puddings.

It is also used for non-food applications

such as in papermaking and in the textile

industry.

There are two approaches to producing

starch - non-fermented starch or soft starch,

and fermented starch or sour starch.

Constraints to cassava fermented starch

production are the variable quality of the

end product. Colour, expansion during

cooking and water absorption are important

qualities of starch.

The basic steps for making starch

Wash,

Chop or grate

Mill with water

Sieve

Mill again

Allow to settle

Separate - Drain the water

Remove the top layers of fine fibre

Ferment (optional)

Remove the starch, break and dry.

5